MEMBRANE

MEMBRANE

Membranes are those important or major factor for any RO system, DM water systems because it is the stage where all type of minerals are rejected and this leads to maintaining the water TDS level as well. The membranes are used in water treatment to separate contaminants from water based on properties such as size or charge. Common membrane processes include Microfiltration (MF), Ultrafiltration (UF), Nano-filtration (NF), Reverse Osmosis(RO), and Electro-dialysis (ED) classified as per pores sizes.

There are many different manufacture of the membranes are as follows:-

- DOW FILMTEC / DUPONT

- HYDRANUTICS

- TORAY

- LANXESS

- KOCH

- LCM

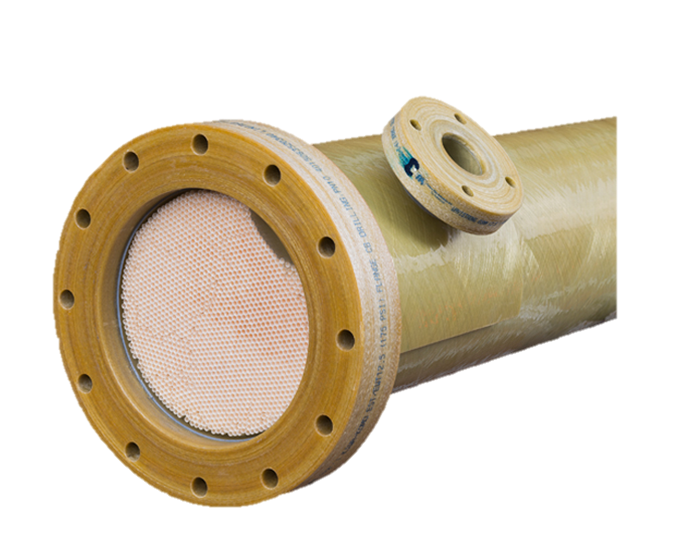

Structure Of Membrane

Variety and Sizes of Membranes

Variety of membranes:-

- Micro – filtration(MF).

- Ultra – filtration(UF).

- Reverse osmosis (RO).

- Nano – filtration (NF).

Sizes of membranes:-

(Note:- All size are made as per there pores so the length and dia (diameter) are consulted there sizes)

- 2.5 and 4 inches in diameter and either 14, 21, 40, 80, or 120 inches in length.

MIRCO FILTRATION (MF) MEMBRANE

- Microfiltration (MF) membrane is loosely defined as a membrane separation process to remove the particles having average molecular weight > 400kDa using membranes with a pore size varying between the 0.05 and 10μm under an operating pressure of less than 2 bar.

- Microfiltration (MF) membrane is made from polymer based membrane as well as inorganic materials, such as:- polyether sulfone, polyethylene, polytetrafluoroethylene, poly vinylidene fluoride, nylon, polyester, polycarbonate, cellulose acetate, and regenerated cellulose), ceramics (aluminum and zirconium oxide), glasses and etc.

- This membrane are widely used to remove the all microscopic particles through out water by the defaulted pore size of requirement.

ULTRA FILTRATION (UF) MEMBRANE

- Ultra filtration (UF) membrane is know as per to remove essentially all colloidal particles (0.01 to 1.0 microns) from water and some of the largest dissolved contaminants. The pore size in a UF membrane is mainly responsible for determining the type and size of contaminants removed.

- Ultra filtration (UF) membrane is made from sulphonated polymers like PSU and PES or fluorinated polymers like PVDF.

- The hollow fiber ultrafiltration membranes are 1.3 mm outside diameter and 0.7 mm inside diameter and are made from PVDF polymer. The fibers are strong due to a combination of PVDF polymer, an asymmetric membrane with smaller pores in the active filtration area, and a high porosity substructure.

- UF membranes based on pore size are listed in Table 6.12. UF membranes are manufactured by the phase-inversion process

REVERSE OSMOSIS (RO) MEMBRANE

- Reverse Osmosis (RO) membrane is the membrane which is used in RO water purification system in which it help to reduce TDS (Total Dissolve Solids) / minerals.

- This membranes plays an key role in wastewater treatment units as they are used to remove salts and other pollutants effectively. RO membrane performance is affected by many different factors such as feed characteristics and operational parameters during operation.

- RO membranes are made of cellulose acetate or polysulfone coated with aromatic polyamides3.

- It is specially designed for High Total Dissolved Solids(TDS) in Water.

- RO membrane technique uses dynamic pressure to overcome the osmotic pressure of the salt solution, hence causing water-selective permeation from the saline side of a membrane to the freshwater side(Faller 1999). Salts are rejected from the membrane, and hence the separation is accomplished.

RO MEMBRANE are having different types of water parameters and elements for working are as follows:

- Tap water elements.

- Brackish water elements.

- Seawater elements.

- Nano filtration elements.

(Note : All element are concludes to Filtec (DOW) a well known brand for membranes this all data and sizes as per Filtec (DOW) membranes manufacture.)